Risolvi oggi l’esigenza di domani

Scopri la vasta gamma dei nostri PRODOTTI fatti su misura per ogni esigenza.

Ideali per acrilico, legno, tessuti e plastica

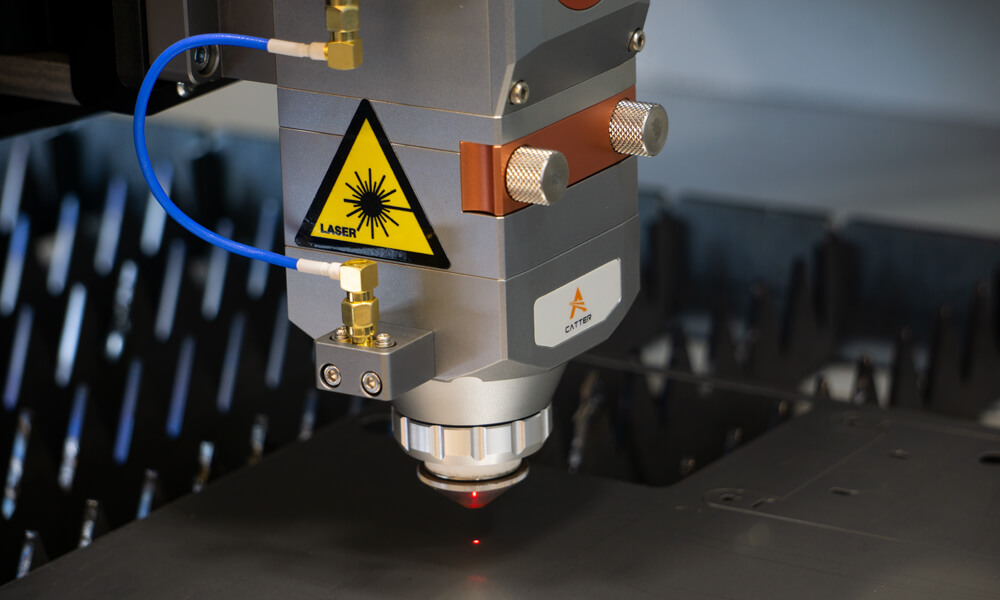

Ideali per metalli, plastiche e materiali compositi (fibre,ecc)

ideali per la saldatura di acciai e leghe metalliche

Ideali per carta, legno, gomma, vetro, ceramica e metalli se verniciati, laccati oppure anodizzati.

Ideali per la marcatura di tutti i tipi di metalli e alcune plastiche

Macchinari industriali realizzati su richiesta

ASSISTENZA SU MACCHINARI LASER

La nostra competenza ci consente di operare su qualsiasi tipo di macchinario laser al fine di risolvere le problematiche che potrebbero compromettere la produzione.